How to Cross the Threshold into Manufacturing Automation

Low-cost options like machine vision systems or part feeders can introduce automation into a single production cell. These small steps can be a proving ground for operations and staff. Yet many small and medium-sized manufacturers have been reluctant to cross the automation threshold.

The benefits of manufacturing automation are extensive. For the shop floor manager benefits include:

- Mitigating the skilled worker shortage

- Improving uptime and productivity

- Reducing operating costs

For the owners and executives benefits might look like:

- Numbers that add up to relatively quick ROI

- Integration with previous investments, such as ERP, SCM and MES software

- A safer environment for highly skilled workers, reducing workplace injuries and associated costs

And for the sales team automation means:

- Higher quality

- Quicker turnaround times

- More solutions to sell

Questions to Ask as You Step into Automation

The good news for the manufacturers who have not taken the automation leap of faith is that you do not need staff expertise for some implementations and integrations. Your existing staff can be part of a smaller process.

Importantly in these scenarios, workers can still feel in control of the equipment. Advantages of taking a small step into automation include:

- You can opt for something that can be redeployed in multiple places on the shop floor, exposing more staff to the technology.

- You can use savings to finance your next investment in automation.

- It will become quicker to deploy subsequent automation.

Taking a first step into automation for many manufacturers is harder than subsequent steps. Companies that take their first step into automation may be used to spending $100,000 or more for a machine that is essential to their operations, but the unknown of investing in a new technology can be daunting. These reluctant companies can ask themselves:

- “How much is our automation budget?”

- “If someone showed us proof of concept in our own shop with a two-week trial, would we invest?” If the answer is no, the discussion can end there. If the answer is yes, then ask: “What’s holding us back?”

Proven Starter Applications for Automation

Manufacturers ready to take a small and cost-effective step into automation can consider these proven applications. These applications are beginner and budget-friendly — and they do not require special staffing. They have successfully been implemented in shops small and big. They are matched to solve common issues that might be holding a manufacturer back.

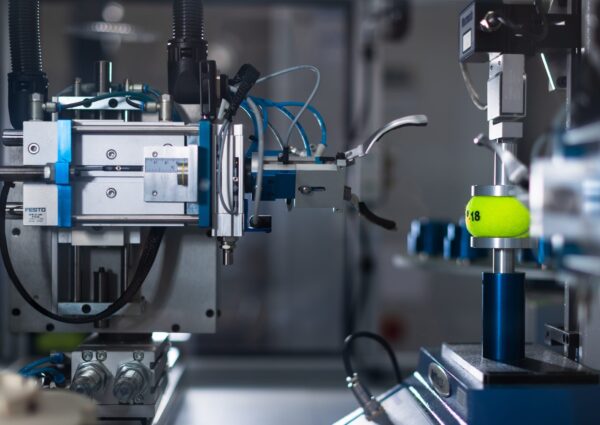

Machine Vision Systems

- Applications: Vision systems for measuring, inspecting and sorting parts and components.

- Benefits: Augments staff; increase throughput; portable; easy to integrate, yields higher quality work.

- Investment: As low as $10,000–$20,000.

- Why Start: The demand for parts traceability is increasing, so you can get onboard now.

Part Feeders

- Applications: Flexible part feeders for counting and sorting components on an assembly line.

- Benefits: Allows faster changeover for more types of parts; portable; multiple uses; simplifies processes to save time.

- Investment: As low as $12,000–$15,000.

- Why Start: Flexible part feeders are excellent for HMLV work and the changing requirements of customers.

Cobots

- Applications: A collaborative robot (cobot) is a robotic assistant on the shop floor.

- Benefits: Intuitive to use; easy to train (deployment in 20 minutes for one task, one week for competency, one month for expertise); increase production; fill staffing gaps; grow capability; portable; easily repurposed.

- Investment: As low as $30,000.

- Why Start: Cobots have incredible versatility and can easily be redeployed. If a product line goes away, a cobot can be reprogrammed; that’s not always the case for machines. You also can let staff try it out to see how it could work for them as opposed to the other way around.

Machine Tending

- Applications: Machine tending for handling parts, tool exchange, pick and place for packaging or assembly, palletizing.

- Benefits: Augments staff; does repetitive, error-prone work flawlessly; doesn’t need a break over multiple shifts.

- Investment: As low as $40,000–$50,000, plus tooling.

- Why Start: As automation becomes more of a table stake and less of a differentiator, at what point will you be afraid of being left behind?

Even Small Steps Can Add up to Significant Improvements

Generally speaking, it’s OK to be afraid to be among the early adopters of potentially breakthrough technology. But you shouldn’t let that fear hold you back; once a concept has been proven, it may be fatal to be among the last to opt in.

In the case of robotics and automation, even small steps will augment your staff and increase your production capacity. Eventually, incremental improvements can add up to a significant payoff. Most importantly, robotics and automation add flexibility and versatility, which can only help you deal with uncertainties.

To learn more about how to take the difficult first step in manufacturing automation and robotics, connect with the experts at your local MEP Center. Together, we can help you navigate technological transformation.

Travis Thiex

Travis Thiex is the automation expert at South Dakota Manufacturing & Technology Solutions, part of the MEP National NetworkTM. He helps small and medium-sized manufacturers identify and install the best automation solutions for their organizations. He also builds custom automation pieces to integrate with manufacturers’ unique assemblies.

This piece is also featured in Industry Week.