How Automation Addresses Workforce Issues

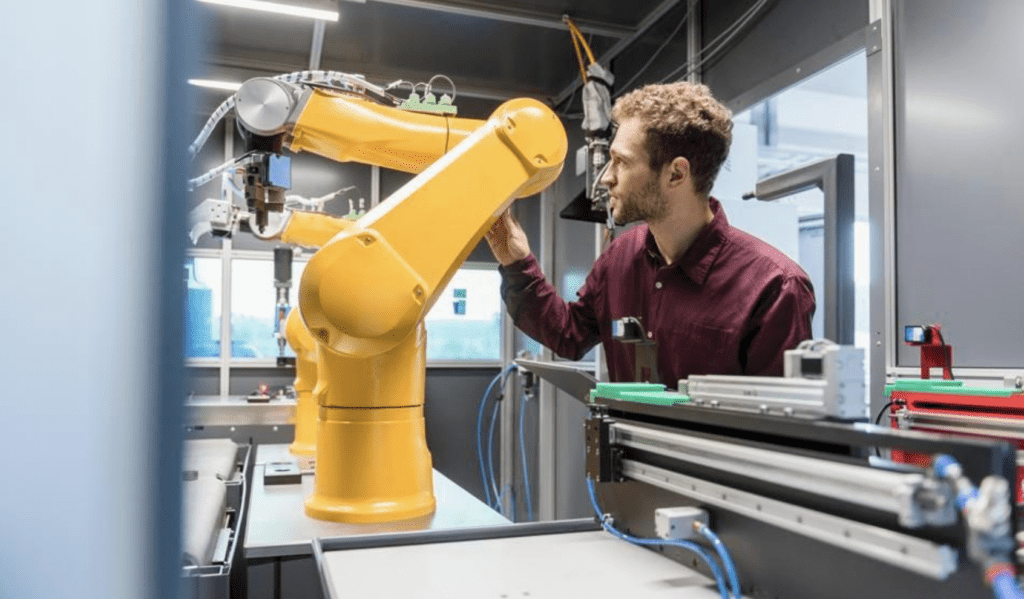

Here’s the first thing to know about automation in business: It’s not about replacing people’s jobs with robots.

“This is all about allowing people to focus on meaningful, challenging work and allowing machines to do the jobs manufacturers can’t keep staffed,” said Mike Vetter, a career entrepreneur with extensive experience in manufacturing and technology.

“We don’t have enough people to sustain the growth and to fulfill the potential of manufacturing, especially in South Dakota. We have to find a way to give people higher-value jobs.”

Vetter spoke recently on the topic at the annual conference of the Governor’s Office of Economic Development and is helping organize a series of events around automation, beginning this month in partnership with South Dakota Manufacturing & Technology Solutions.

“I would say in South Dakota we’re still in the early-adopter phase, so there’s a lot of room for businesses to embrace this,” he said.

The realization – driven by supply chain constraints – that overseas manufacturing can present massive challenges also underscores the need to automate.

“The only way we’re going to onshore is by using automation. We simply don’t have enough people to build what we consume in this country,” Vetter said. “But it’s still an awareness issue for a lot of manufacturers, especially because they don’t realize automation is a solution to their workforce problem.”

For instance, consider these three things to know about automation:

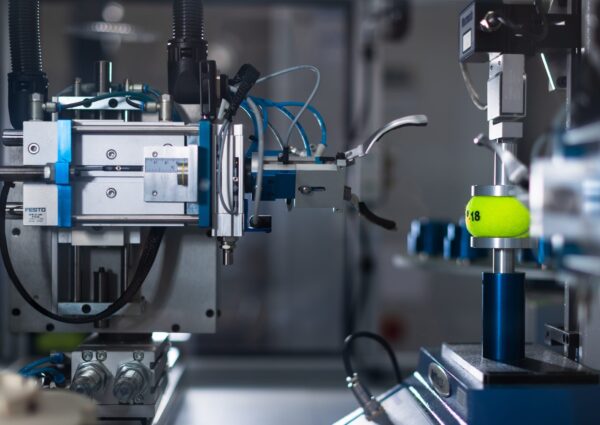

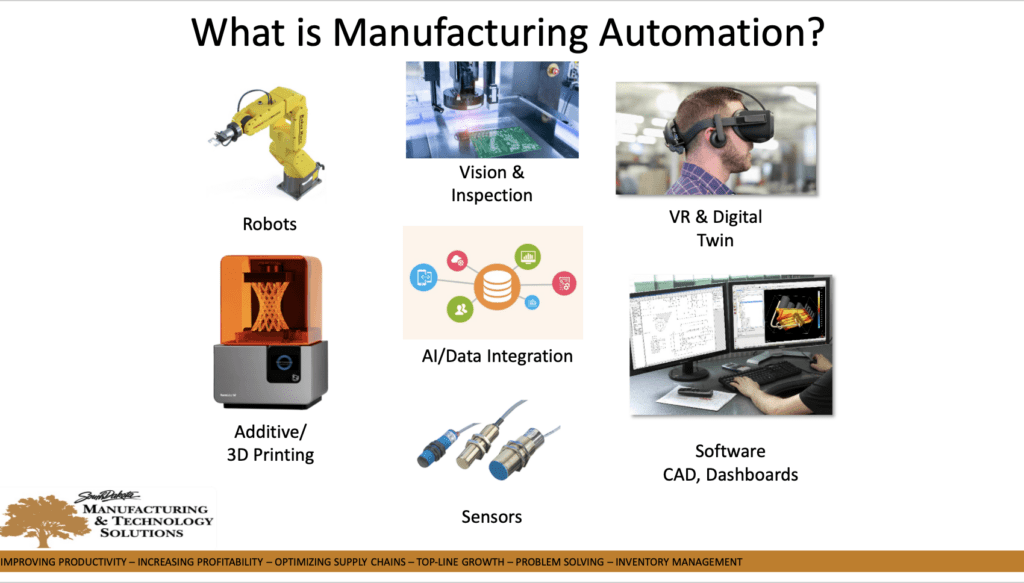

It’s about more than robots

While automation does involve robots, it’s also much broader. Take a look:

“There are traditional robots, but it’s also using artificial intelligence and vision to look at things and react to them,” Vetter said. “There’s designing in 3D and even creating VR experiences for training. You can build your whole shop floor in VR, design the product virtually and then build it physically.”

The field also encompasses sensor technology and 3D printing.

“And you also don’t need a team of automation tech wizards on your staff to make it work,” Vetter said. “There are off-the-shelf products now that can do the job, and you’ll be able to learn them.”

It’s likely not cost-prohibitive

If all that sounds like it must require a lot of upfront capital, that’s not necessarily true.

For example: “A robotic welder used to be a $250,000 investment, and now it’s a fraction of the cost,” Vetter said. “Robotic welders are also dramatically more simple to operate – you can train someone to weld with a robot after lunch, and they will be welding the same afternoon. There will be a 400,000-welder shortage in the U.S. by 2024, and using robotic welding is a way to grow our ability to fabricate in the U.S. with the people we already have in the field.”

Most manufacturers can begin by automating simple processes that are “low hanging fruit” – they are easy to automate and tasks that are difficult to staff. South Dakota Manufacturing & Technology Solutions, or MTS, targets the return on investment period, or ROI, to be less than two years, and there are virtually always tasks that fit the bill.

“If you’re automating something you’re struggling so much to hire, that’s a good candidate for automation as well,” Vetter said. “And it’s also less expensive than the alternative, which is not taking an order.”

It’s easy to get started

Not sure how to begin tackling your own automation journey? MTS will help your business with a process mapping.

“Effectively, you don’t want to go out and buy a hammer when the thing you need is a screwdriver,” Vetter said.

“So before you pursue automation, MTS will map out the process in detail and identify your biggest bottleneck, the thing that prevents you from getting more product out the door. And if your bottlenecks can be automated, it’s a good use of capital. So that will help prepare you for automation and make sure you don’t accidentally buy equipment that’s not right for your needs.”

There will be a series of Road Shows held this year that also can help you get started. The first one, on May 12 in Yankton, will cover robotic welding, 3D vision in production and additive manufacturing.

Speaker John McElligott of York Exponential will cover “The rise and fall of American manufacturing: How the pandemic, TikTok, robots and artificial intelligence have shaped the future of manufacturing and what you can do about it.”