The 411 on the Automation 101 Course

One of the key challenges for many manufacturers in the state of South Dakota is the demand for their products is growing. Another challenge is that South Dakota is a small state in terms of population, so we need to take the existing workforce we do have and help them become even more productive than they are today. A solution to that problem can be using automation, which has the potential to be a huge advantage for our state’s manufacturers.

At South Dakota Manufacturing and Technology Solutions (MTS), our mission is to help the state’s manufacturers prosper and grow. We are passionate about helping manufacturers grow using automation when applicable.

Manufacturers are having a hard time hiring enough people to keep up with the demand they already have, but on the flip side, they’re not always fully utilizing the people they already have in place. Automation is a key aspect of helping both sides. Manufactures can potentially use automation to fill in gaps in employment and utilize existing employees better by uptraining or upskilling their workforce. Automation can help keep the workforce safe and find fulfillment in their work, too.

At MTS, we are focused on helping manufacturers identify areas of their business that are candidates for using automation to complement what they’re already doing in their business today.

There are three key advantages of why manufacturers could put automation in their company.

Increase productivity with their team and enable them to do more.

Improve safety, especially on repetitive jobs.

Increase employee retention. Employees want to work at a company that has the proper tools and equipment to help them do their jobs better every day.

Introducing Automation 101

With that, we developed an Automation 101 training program to educate people on different aspects of automation and help spread awareness of its potential. This one-day workshop will also help overcome people's initial fear when introducing new concepts like this to their companies.

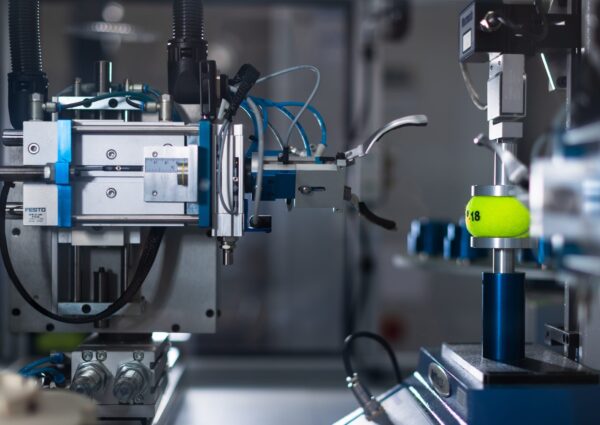

The Automation 101 workshop takes people through a completely manual assembly process and evolves into a completely automated assembly process. As the day progresses, attendees will go through a series of automation rounds at a fictitious manufacturing facility. Attendees are introduced to concepts like part presentation, machine tending, and camera inspection in a mixture of classroom time and hands-on instruction.

Each round will build on the automation lesson taught before the round. Attendees will apply the new concept to the automation simulation and see the new automation tool's impact on the company’s throughput. After each round, attendees will measure their results and discuss their discoveries before moving on to the next section.

Automation 101 Lesson Overview

Lesson 1 - Principles of Lean Automation

Lesson 2 - Process Mapping the Work Cell, Overview of Collaborative Robots (Cobots), and Safety Requirements

Lesson 3 - Vision Systems, ERP transactions

Lesson 4 - Vision Systems with Deep Learning, Lenses, and Lighting, 3D Laser Scanners, Intelligent Vibrating Feeder System, and “real-time” dashboard to monitor work cell activities

Attendees leave the Automation 101 training with a better understanding of what automation can do for their organization and be able to see new opportunities for application.

Additional Automation Assistance

To help manufacturers take advantage of automation, MTS offers complementary automation evaluations to come onsite to manufacturing facilities and help identify if there are potential places in the process that could benefit from automation. From there, we can help them determine where the best opportunities for automation can occur by mapping out the process. With that, we can also help show where the greatest return on investment will be to start with first. Instead of buying equipment and then figuring out where it should go, we help identify the parts of their process that could use automation. We also help crunch the numbers to make sure it will indeed help with productivity and that it can pay for itself within a reasonable amount of time. The MTS automation lab also has different pieces of equipment that are available for clients to borrow and test before purchasing, when applicable.

By making automation easier to access and learn about, our goal is to help manufacturers move forward. Learn more about the automation 101 course offering here.